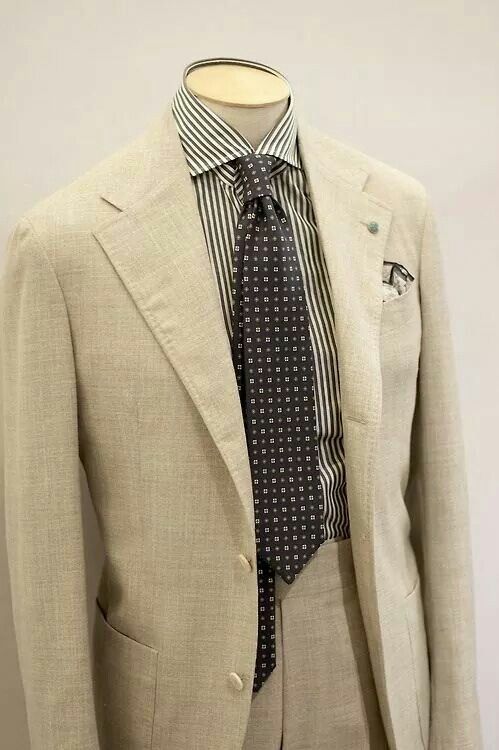

The Science Behind Suit Durability: Stitch Count, Fusing & Fabric Quality

Why true craftsmanship matters when choosing a tailor in Hoi An

(4).jpg)

Durability Is Not an Accident

When clients visit a tailor in Hoi An, many are drawn by style, fabric patterns, or the promise of a fast turnaround. But seasoned tailors know that true quality lies far deeper than appearance. A well-made suit is not defined by how it looks on the first day — but by how it performs after years of wear.

At a professional bespoke tailor in Hoi An, durability is not a marketing term; it is a result of craftsmanship, structure, and technical understanding. Three elements ultimately determine whether a suit will age beautifully or lose its shape within months:

- Stitch count

- Construction method (fusing and canvas)

- Fabric quality

This article explores the science behind suit durability, explained through the lens of an experienced tailor in Hoi An who works daily with international clients seeking long-lasting, high-quality bespoke garments.

1. Stitch Count – The Foundation of Structural Integrity

Why every great suit begins with precision stitching

In tailoring, stitch count refers to the number of stitches per inch used to assemble a garment. While invisible to most clients, it is one of the clearest indicators of craftsmanship.

Why stitch density matters

A higher stitch count creates:

- Stronger seams that resist tension and wear

- Better flexibility and movement

- Cleaner lines that retain shape over time

Low-quality, mass-produced suits often use 6–8 stitches per inch, prioritizing speed over durability. In contrast, a professional tailor in Hoi An typically applies 10–12 stitches per inch, especially in high-stress areas such as:

- Armholes

- Lapels

- Shoulder seams

- Jacket side seams

These areas experience constant movement. With insufficient stitching, fabric eventually pulls, puckers, or loses alignment.

Hand-finishing vs machine stitching

While machines ensure consistency, true bespoke tailoring relies on hand-finishing for key structural zones:

- Collar attachment

- Sleeve setting

- Lapel shaping

Hand stitching allows micro-adjustments that machines cannot replicate. This is why bespoke suits from experienced Hoi An tailors drape more naturally and feel lighter despite stronger construction.

2. Fusing & Canvas Construction – The Hidden Architecture of a Suit

.jpg)

What lies beneath the fabric defines the suit’s lifespan

Many clients are surprised to learn that what they cannot see inside the jacket matters more than the outer cloth itself.

Understanding suit construction types

There are three primary methods used in tailoring:

1. Fused Construction

- Uses adhesive bonding to attach the inner lining

- Faster and cheaper to produce

- Prone to bubbling, peeling, and stiffness over time

This method is common in mass-market suits but rarely used by reputable tailors in Hoi An for long-term garments.

2. Half-Canvas Construction

- Combines canvas in the chest area with fused lower sections

- Offers a balance between structure and cost

- Common in mid-range bespoke tailoring

3. Full Canvas Construction (Premium Standard)

- Entire front panel is built with floating canvas

- Allows the suit to mold naturally to the wearer’s body

- Improves breathability, durability, and comfort over years

At a professional bespoke tailor in Hoi An, full canvas construction is preferred for clients who want longevity, structure, and refinement.

Why canvas matters more over time

Unlike fused jackets, a canvas-constructed suit adapts to your posture as you wear it. Over months of use, it becomes uniquely yours — forming around your chest, shoulders, and movement patterns. This is why well-made suits often look better after a year than they did on day one.

3. Fabric Quality – The Final Determining Factor of Longevity

A suit can only be as good as the cloth it’s made from

Even perfect tailoring cannot compensate for poor fabric. Professional tailors in Hoi An are selective not only about design but also about textile origin, weave, and fiber quality.

Key fabric factors that affect durability

1. Fiber Type

- Wool (Super 100s–130s): Ideal balance between softness and resilience

- Wool blends (wool–silk, wool–cashmere): Added luxury but require expert handling

- Linen & cotton: Breathable but need precise construction to avoid deformation

Higher Super numbers (140s–180s) may feel luxurious but are more delicate. A skilled tailor will recommend fabric based on lifestyle, not trends.

2. Weave Structure

The weave determines strength and recovery:

- Twill weaves offer durability and crease resistance

- Plain weaves breathe better but wrinkle more easily

- High-twist yarns increase resilience in warm climates like Hoi An

A knowledgeable tailor in Hoi An selects fabrics not just for appearance, but for climate, usage frequency, and client lifestyle.

3. Fabric Finishing & Shrinkage Control

Reputable tailoring houses pre-treat fabrics to reduce shrinkage and distortion after tailoring. This step, often skipped in mass production, ensures the suit maintains its proportions even after years of wear.

Why Tailor Hoi An Standards Matter

Hoi An has earned international recognition not simply for affordability, but for craftsmanship built over generations. Skilled artisans here understand that:

- A suit must perform in real life, not just under showroom lights

- Durability is the true measure of luxury

- A well-constructed suit reflects the discipline of its maker

When you choose a reputable tailor in Hoi An, you’re investing in structure, balance, and long-term value — not just a garment.

Conclusion: True Quality Is Built, Not Marketed

A suit’s beauty may catch the eye, but its construction determines its future. Stitch count, fusing technique, and fabric quality work together to create a garment that lasts years — sometimes decades.

For those seeking more than just a quick tailor experience, understanding these principles is essential. And for those who value craftsmanship, a skilled Hoi An tailor remains one of the best choices in the world for bespoke menswear.

MAYA TAILOR HOI AN

📍 Address: 102 Trần Phú, Phường Minh An, Hội An, Quảng Nam, Việt Nam

📞 Phone: 0905992597

✉ Email: mayadesign102@gmail.com

🌐 Website: besttailorhoian.com